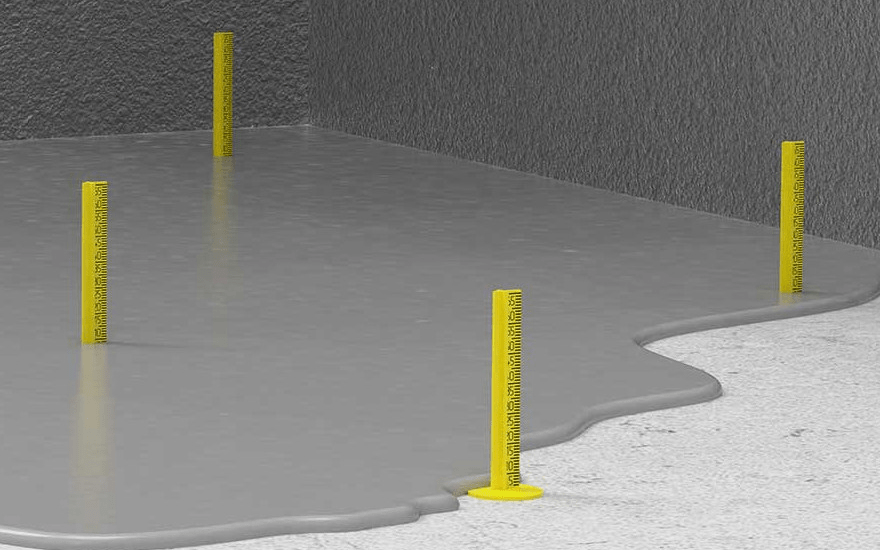

Self-leveling ground plaster(hereinafter referred to as self-leveling plaster) can flow and level on the concrete floor sub-crust, that is, form a smooth surface under the action of its gravity and become an ideal leveling layer for building floors—base material for floors and various ground decoration materials. The traditional construction method of the indoor ground of the building is to first make a sub-crust on the floor (usually lime-slag tamping or concrete sub-crust), then use cement mortar as a screed, and then complete a surface course. This method is labor-intensive and time-consuming, especially the leveling layer, which needs to be smoothed by hand. Instead, a leveling layer can be poured directly on the sub-crust layer with self-leveling plaster. After it hardens, users can make various finishing layers on the plaster leveling layer according to their wishes.

The ground constructed with self-leveling plaster has accurate dimensions, high flatness, no hollowing, and no cracking. After 24 hours of watering, you can walk on it; after 48 hours, you can work on it. Trimming is generally not required after drying, and its flatness can meet high-level requirements. It can directly lay on the ground with PVC boards or carpets. If it is made of solid wood floor or pasted with floor tiles, it can reduce the floor’s quality and save the amount of adhesive. Since the thermal conductivity of the self-leveling gypsum floor is much lower than that of the cement mortar floor, there is no cold feeling when stepping on it.

Using self-leveling ground materials to make high-standard indoor floors saves time and labor and can be completed without advanced plasterers. The construction work is easy and convenient with high efficiency. And people can adopt pumping construction; therefore, the daily paving area can reach 800 to 1,000 square meters. With this method, people can also make large-area ground without gaps.

Leave a comment